EquipTalk Ltd. is dedicated to develop software-defined high-end equipments. Leveraging the aerospace measurement technology as the next-generation digital foundation for high-end equipments, EquipTalk strives to empower high-end equipment in all aspects.

As EquipTalk's data base, Shifu spares EquipTalk developers the need to develop the underlying infrastructure and device abstraction layer, transforming traditional IoT application development into simple web development, greatly improving the efficiency, quality and reusability of IoT application development.

User Profile

The core team of EquipTalk comes from universities both at home and abroad, with many famous professors and experts in the field of national defense, and has been deeply engaged in the field of rocket testing for more than 20 years, and has developed rocket testing systems deployed in China's four major launch sites and industrial sectors, as four series of China (Long March 5, Long March 3, As the core equipment of four series of rockets (Long March 5, Long March 3, Long March 2 and upper stage series), it has guaranteed hundreds of major space engineering tasks such as China's Beidou system network, space station, lunar exploration and fire exploration.

EquipTalk mainly serves the manufacturers and users of high-end complex equipment in the field of aerospace, rail transportation, ships and marine engineering, energy, etc. to ensure the reliable and safe production and use of high-end equipment.

Objectives

- achieve the integration of measurement, control and management of high-end equipment

- improve system availability to 99.9999%

- decouple hardware and software, significantly increase the software iteration speed

- ensure full-link network security

Required Equipment

Generalized and modularized rocket rapid test equipment (four models)

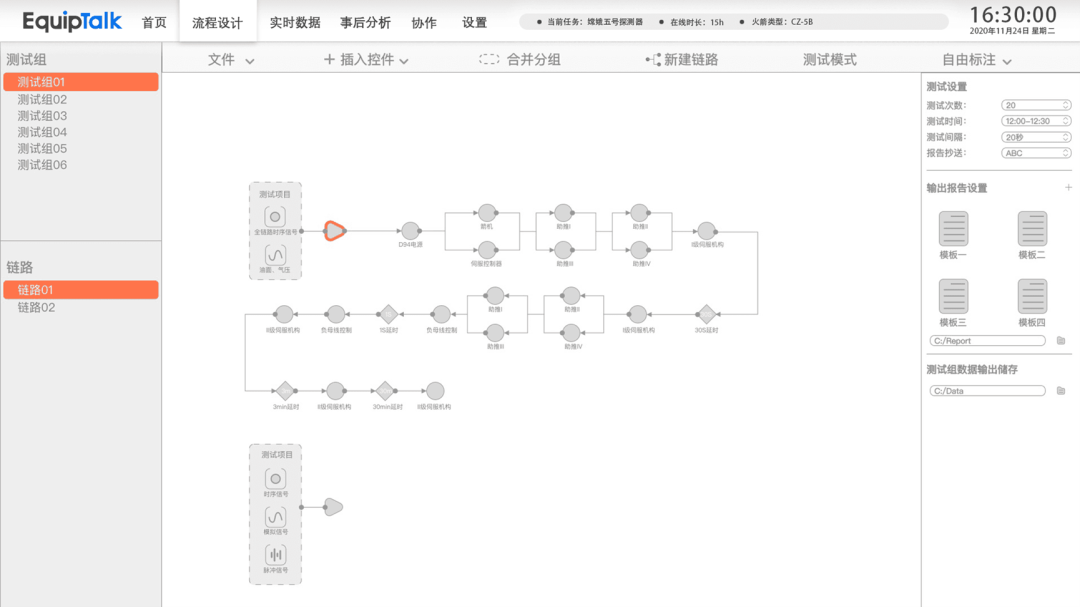

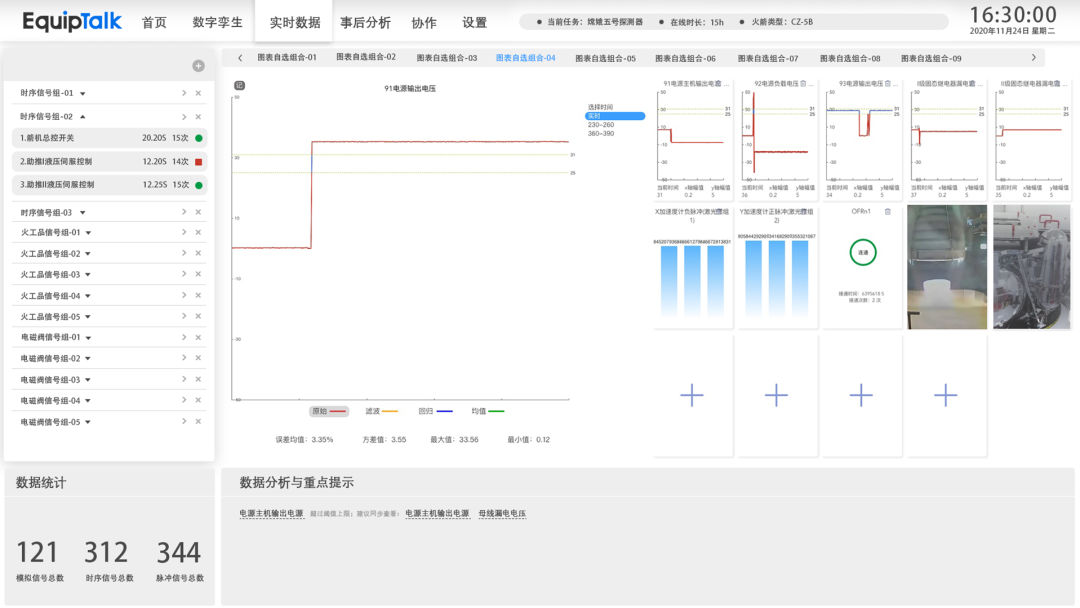

Product interface and architecture

EquipTalk data control platform

EquipTalk's overall architecture diagram

What is Shifu

Shifu is the next generation of open source industrial IoT development framework, making developing an industrial scenario as simple as developing a Web app. Shifu's high scalability allows it to access almost any device and protocol. Once integrating a device, Shifu generates a digital twin of the connected device in the form of a microservice in the system and opens up the device data and capabilities in the form of APIs. In this way, traditional IoT application development is reduced to simple web development, which greatly improves the efficiency, quality and reusability of IoT application development.

Shifu acts as EquipTalk's data base, sparing EquipTalk developers the need to develop the underlying infrastructure and device abstraction layer. As a result, EquipTalk is able to focus on developing business logic, abstracting the expertise of several well-known professors and experts in the defense field into the EquipTalk software platform, and creating a one-stop solution for high-end equipment testing.

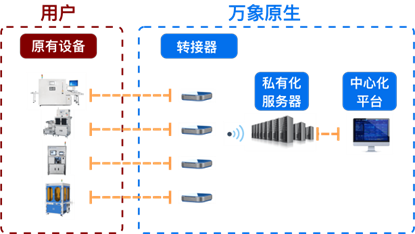

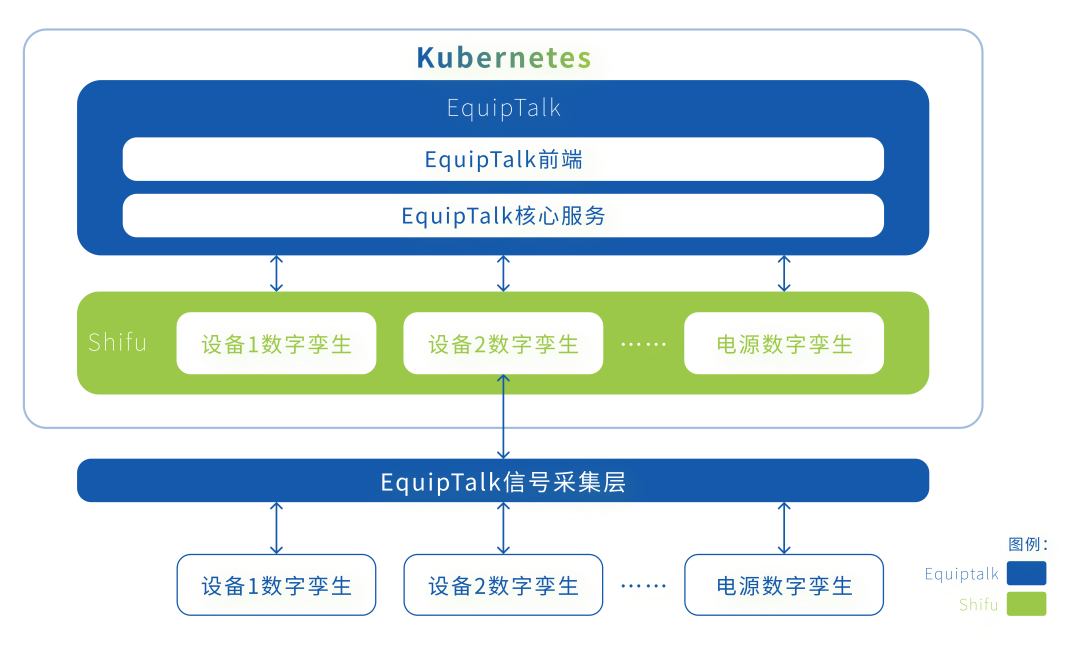

The new architecture of EquipTalk after integrating Shifu

Overall architecture diagram

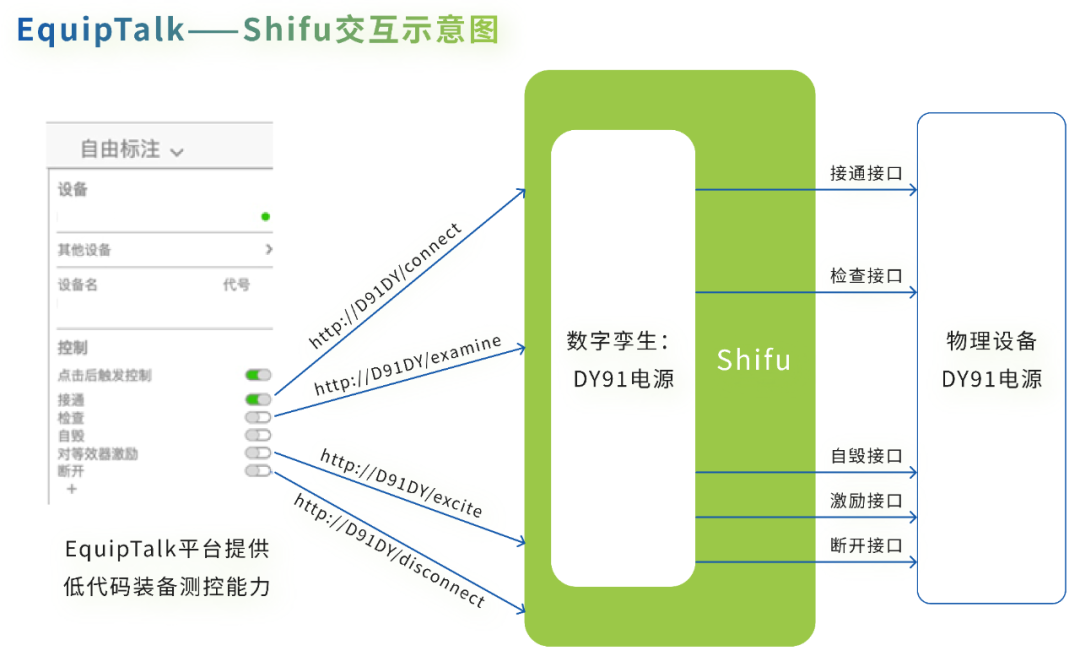

If we take out only the architecture related to the D91DY power supply, we have the following schematic

The following diagram shows the interaction between EquipTalk and Shifu

Outcome

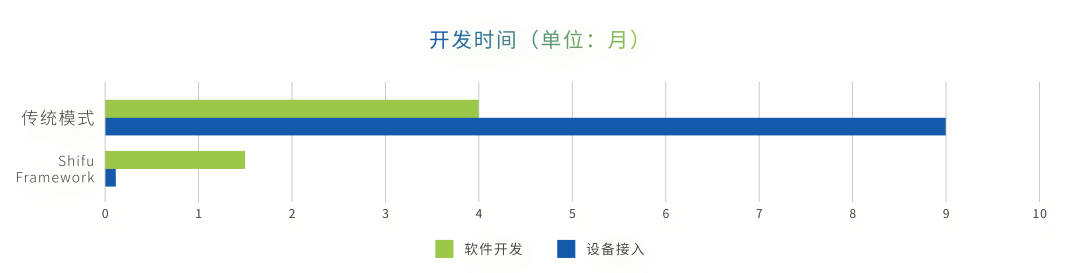

- 85% reduction in device integration cost with Shifu's device access module

- 200% increase in application development efficiency with Shifu's application development module

- Increase overall system availability to 99.9999% with Shifu's system operation and maintenance module

Summary

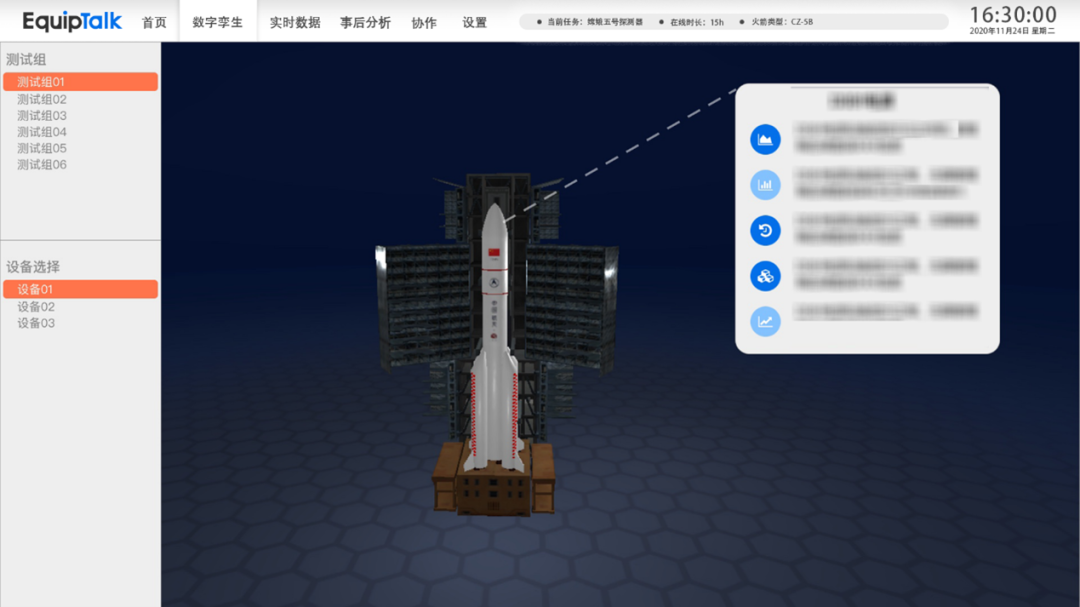

This paper introduces the joint solution of EquipTalk and Shifu. The solution has successfully empowered high-end equipment, including Long March rockets, created customized measurement and control equipment for customers. The solution bears the characteristics of rapid deployment and flexible configuration, helping enterprises to reduce costs and increase efficiency. The solution uses distributed wireless communication to shed off the shackles of cables, using central measurement and control that is more efficient and stable. The solution uses massive data to extend digital applications including life-cycle health management and digital twin. The joint solution significantly improves the efficiency of development, production and operation and maintenance.